Data logging...

With the larger turbo and fresh rebuild, the car felt amazing--white-knuckled quick. I had been gradually increasing boost and was running around 13-14 psi (which spiked to 15 or so, then leveled off), and I doubted that I'd increase it that much.

Recently, I had installed an electronic exhaust cut-out (see below) that effectively eliminated half of the exhaust/muffler. The cut-out, which is a Y-shaped pipe with an electronically controlled valve (that looks like a throttle body) on one of the legs, effectively makes the car run as if it only had a downpipe. The valve opens by a switch in the cabin on the center console, and it allows an extra psi or so and even leaner A/F ratios when open, in case the driver were to feel even more power-hungry...

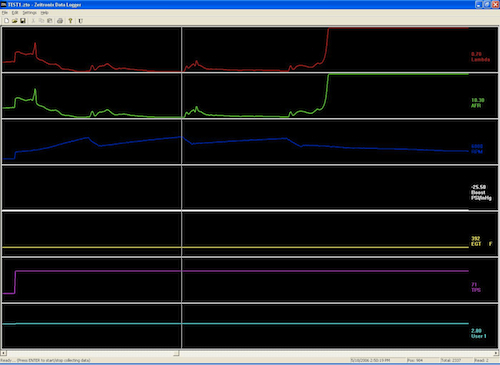

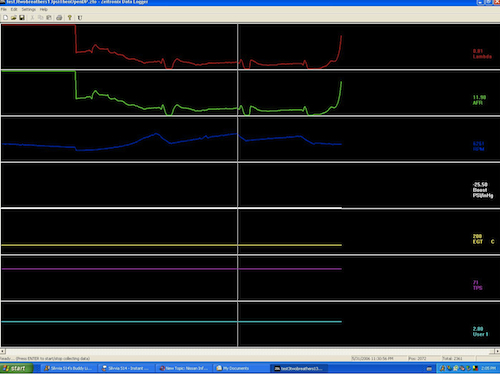

But even with the cut-out open, I knew the engine was capable of more performance if the air/fuel ratios were leaner. I knew the engine was running rich due to the intrinsically conservative tune of the JWT ECU, but I wasn't sure exactly HOW rich. After I purchased a Zeitronix ZT-2 A/F ratio monitor, digital display (to the top left of the shift knob in the picture), and software, I was able to get a definitive answer via data-logging.

Running unacceptably rich.

I was dismayed to find out just how rich the JWT's tunes are...Without adjusting anything, the A/Fs were about 10.0:1 WOT in 2nd, 3rd, and 4th gear. A ratio of 12.0:1, especially with my huge intercooler and methanol injection, would clearly add some power--not to mention fuel efficiency.

Since I had an adjustable Aeromotive FPR, I bumped the fuel pressure down about 5 psi to 29 psi to lean it out, but the a/fs were still very rich (10.3:1 or so). See below:

The reverse hacked MAFS (Mass Air Flow Sensor)

I knew I couldn't just keep bumping the fuel pressure down without adversely affecting the injector spray pattern, so I came up with a clever solution. Before Enthalpy Tuning and AEM EMS even existed, for those of you who were still KA-T, you will remember not much was available for engine management. A hacked MAFS (a la Orion) was the hot-topic among do-it-yourself tuners. So I basically worked backwards from the hacked MAFS concept. A hacked MAFS basically tricks the MAFS into thinking the engine is ingesting more air than it is, thereby causing the ECU to richen up the mixture to compensate for a boosted KA24DE. So I wanted to trick the MAFS into thinking the engine was ingesting less air than it was so that when another source of oxygen was added, the ratio would lean out.

I already had a 5/8" nipple welded to my turbo inlet pipe where a hose from the PCV (on the valve cover) was attached. This nipple was AFTER my Cobra MAFS. So what I did was simply put a breather filter on that PCV system from the valve cover, and then attached a 5/8" vacuum hose with a breather filter to this nipple on the turbo inlet, meaning a steady stream of 5/8" air would be entering the turbo inlet after my MAFS, WITHOUT being metered by the MAFS, meaning it should, in theory, create a leaner condition. It worked, and without any detrimental side-effects, and made the A/Fs noticeably (by seat-of-the-pants and by data-logging) leaner.

I also already had a residual 1/4" nipple welded to the turbo inlet pipe, also after the MAFS; a long time ago when I was first turbocharging the engine, I bled air from the wastegate line into the inlet to increase boost at the turbocharger. It used to be plugged because my new wastegate lets me run 14 psi without any tricking of the wastegate line. So I figured if a 5/8" stream of fresh, unmetered air made the A/Fs leaner, then 1/4" more would make it even leaner, and it did. I used a panty-hose as a filter for this 1/4" line for an initial test, but will eventually somehow tie it into the other 5/8" hose (yeah, I've been critical of jury-rigging set-ups, and I'm guilty here, but it really does work and this was merely a test). So for those who are good at math, that means I now have a 7/8" stream of unmetered fresh air being introduced to the turbo past the MAFS.

Using these 2 breather lines, A/Fs were now a MUCH better 11.3:1 (at the richest, mostly it was around 11.5:1). When the exhaust cut-out on the downpipe is open, the mixture leans out even a little more to a very respectable 11.9:1 (partly due to the freer breathing engine, partly due to the 1 psi extra gained due to less back-pressure) in third gear at 6000+ rpm.

Seeing how effective my modification was, I decided to make the bypass tube look a bit more professional and less jury-rigged. After initially testing with rubber hose and a 5/8"nipple and 1/4" nipple, I ordered 3/4" OD (.62" ID) T-304 stainless-steel tubing from www.burnsstainless.com (by the way, great website; they sell everything from inconel to aluminum, and it's ALL in stock).

If you look closely in the pictures, you will see a small K&N filter that drops into the fender well, right next to where the main air filter is (both cold air). You will also notice in the shot of the engine bay that I finally got those two aluminum intercooler pipes welded together (instead of using a coupler and hose clamps) while I was getting the bypass tube welded.

It felt like a Porsche, but I wanted some concrete horsepower numbers...

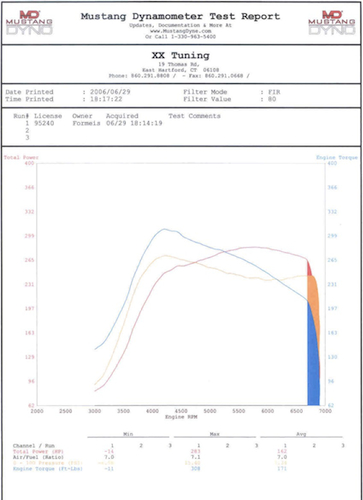

Before the first dyno test in the summer of 2006, the story of my 240sx project had seemed a cruel vindication of Murphy's Law: "if anything can go wrong, it will go wrong." But with a newly upgraded T3 Super 60 turbo, a fresh rebuild, forged Crower connecting rods and some optimism, I went to the dyno to see how much power it wasreally making; using the seat-of-my-pants as a gauge is far too subjective...I was aiming for 330 rear-wheel horsepower at 16 psi, which I thought to be a very attainable, realistic goal.

Surprise, surprise...I fell short of my goal again.

The blue line is torque, red line is horsepower, orange line is boost pressure. My dad forgot to bring the digital camera to take a video (d'oh), but it sounded so beautiful. That's the first time I had ever heard the car from outside, and wow. Too bad it wasn't putting its money where its mouth was, so to speak.

The engine made 283 rwhp and 309 rwtq, 50 rwhp less than I was hoping for, although the torque number was at least a bit more respectable.

Nevertheless, it was amazing how fast the car feels even at this level...I can't even imagine what it'd feel like if it were making how much I was hoping it to make.

About the dyno test:

-Weather was miserable: muggy, humid, hot, 87 degrees.

-Only one external fan was used on the car, and it looked to be rather small--it wasn't one of those huge diameter industrial type fans, but one of the smaller ones that looked like a turbo snail. The WRX next to mine being tuned had one of those huge industrial sized fans AND two of the small ones. Of course, me being non-confrontational and non-assertive, I didn't bother saying anything..

-I didn't even get to do the pulls! No clue why, apparently this was the dyno shop's policy. All pulls were done in 3rd gear.

-All runs were taken on a Mustang Dynamometer. I've heard these read low compared to others, at least that's what one of the employees said. All of the figures were "SAE corrected" according to the man who did the pulls..

-A/Fs when this power was made: 11.7-12:1 (ie, NOT RICH AT ALL, actually a little on the lean-side, but this is fine because the methanol more than helps out here).

Overall, I was perplexed: my engine was only making about 40 more rwhp than all of those bolt-on kits made right out of the box, on stock engines, at only 8 psi. It made no sense to me. Compression was tested a few days ago and is 166 psi across the board. Car runs perfectly, is not running rich, and the boost stays relatively constant.

So why in HELL wasI about 50 rwhp down from what I should have been making?!?! I was sure that ~10-15 more hp could have been made advancing the timing at the distributor, but I didn't have anything to record timing with me at the time.

At least the car looked beautiful from the outside...

And Murphy's Law is once again instantiated...

A few days before the dyno appointment just discussed, I noticed blueish-white smoke that reeks of oil coming out of my exhaust while I was at the drive-thru of Dunkin' Donuts.

Immediately I assumed the worst, so I did a compression test: 166 psi across the board, and the car still feltplenty fast, and not low on power compared to when there wasn't any smoke.

Turbo still spooled up quickly, sounded phenomenal, and hit 15 psi and held it.

The turbo was a BRAND NEW (NOT refurbished or rebuilt) Garrett T3 Super 60 with a .63 a/r turbine, stage III turbine wheel, and a 360 degree thrust bearing. It had been used for about 2000 miles.

For the first 1000 miles while the engine was being broken in, there was no oil-restrictor on the oil feed line. The turbo didn't boost past 8 psi, but there wasn't a single bit of smoke whatsoever for the first 1000 miles while running without a restrictor. When I turned up the boost, I added an oil restrictor, because everyone on the KA-T forums insisted that it was needed, and that without it, excessive oil pressure to the bearings will cause turbo seal failure. The only other thing I have changed since breaking it in is using a valve-cover breather for the PCV line instead of having it routed to the turbo inlet pipe, which is where it was plumbed before.

The restrictor used is .075" or about 1/13". Most people use 1/16" or .060". The difference in size for the restrictor I used is most surely negligible.

Anyhow, with this restrictor, for about 1000 miles there was no smoke whatsoever. Then all of a sudden one day it started smoking quite a bit of blueish-white smoke. I had my dad follow me and he said the smoke increased when I got on throttle, but not ALL the time; it also smoked *sometimes* when idling.

So where had I gone wrong? I used an oil restrictor for the sole purpose of PREVENTING turbo seal damage, yet it happened anyway. Brand new $500 turbo. Needless to say, I was frustrated at yet another setback.

The turbo drain-line was not the problem; it's stainless steel hose with aeroquip fittings, the fitting on the pan is plenty high, and I was running on the low-side of the dip-stick just to make sure the oil wouldn't back up and cause turbo seal failure.

I knew BB turbos need an oil restrictor, and I had heard that the SR20DET engines had a built-in restrictor in the turbo feed line...but many other car manufacturers with turbocharged models did NOT use restrictors (like Volvo, Saab, etc).

Could it be that the turbo WASN'T getting enough oil, that is, because of the restrictor the flow was prevented enough such that there wasn't a "hydrodnyamic wedge" of oil surrounding the bearing (dad's words)? Doing some research on turbo failure, I found out that it's usually the bearings that fail which cause subsequent seal leakage...the seals don't just "blow". And bearing failure is caused by a LACK of lubrication.

I was understandably irritated, and once again I contemplated getting rid of the car...it seemed to be little more than a financial sinkhole.

In any case, I went through with the first dyno test anyway. With the T3 Super 60 seemingly failing me, and my dyno numbers unacceptably paltry, I took advice from the KA-T forum and decided to ONCE AND FOR ALL purchase a turbo large enough to make 400+ rwhp:

Can you guess which turbo is the GT32?!

The GT32 was expensive at $650, but I knew I could get at least $450 for my T3 Super 60 (after I took it out there was little to no shaft play--it felt like a new turbo). I ordered the turbo from AMS/Turbo 240 (http://www.turbo240.com) and it came very quickly. Hats off to them.

The compressor was pleasingly larger than I thought it'd be! I hoped that one thing would go my way and that it'd fit my current setup. It did, and it was a tight fit indeed, but not too tight to fit a turbo blanket on the exhaust turbine, which drastically reduced underhood temps.

The massive turbo's size talked the talk, but did the GT32 walk the walk?

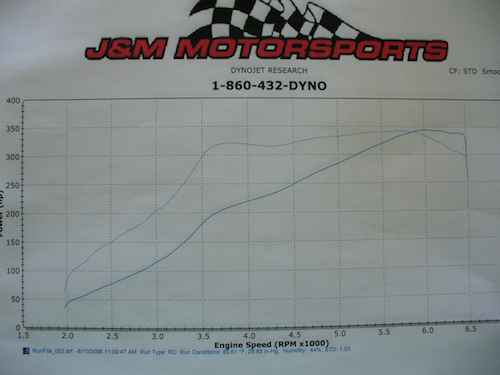

I decided to test the car's horsepower again, this time on what most everyone uses to measure rwhp: a traditional dynojet (I know that mustang dynos run about 10 % lower than dynojets...)

This time, at 16.5 psi, A/Fs in the high 11's, I made 343 rwhp, 310 rwtq (interesting how the larger turbo completely reversed the powerband of the T3 Super 60). The torque curve is as flat as a board. LOTS of useable power.

Here's a video of the dyno test. It's too bad the video got cut off right before the maximum RPM.

So at the end of the summer of 2006, over four years after I first picked up my 240sx, I was FINALLY satisfied with how the car performed, both in acceleration and handling. Above is a video of the dyno--unfortunately it cuts out just before hitting peak RPM.

Taking a break from the engine, the next upgrade I made was purely aesthetic, but transformed the car into an absolute emerald-green jewel that looked as good as it performed. See "pictures" page to see exterior pictures of the 240sx first as a Zenki, then as a Kouki!