Catastrophe.

Now what makes the forthcoming story at least sardonically entertaining is the irony involved. Okay. RIGHT after the engine had been broken-in for 1000 miles, (August of 2005) I increased the boost to 16 psi, which was pumping about the same amount of air as 12-13 psi from the larger and more popular T3/T4 50 trim turbo. And guess what failed in the engine? The ONE component that was not replaced during the engine rebuild--the connecting rods. Conventional KA-T wisdom at the time said that stock connecting rods were plenty beefy enough to handle that amount of boost and power. Apparently mine were not. I think the best way to describe how painful the experience of seeing my dream engine disintegrate into fragments of iron and steel, would be to copy verbatim the thread I posted on Nico's KA-T forum, 15 minutes after I got home from the debacle:

"Yup, another blown up KA-T.

Running 16 psi from a T3 super 60 (equates to about 12-13 psi from a T3/T4 50 trim hybrid) at 3500 rpm in 5th gear. #3 rod right through the block. Parts of the rod and block all over the road, oil everywhere. I was a mile from home and pulled over to a friend's, whose house was right where the explosion occurred. The engine had been professionally rebuilt about 1000 miles ago. I was running a JWT ECU, Ford Cobra MAFS, MSD 50 lb/hr fuel injectors, PK top-feed fuel rail, alcohol injection, a large FMIC, and 9:1 forged wisecos. No detonation. Sounded just like Foster [fellow member whose built KA-T exploded soon after break-in] described, except "luckily" for me, the rod didn't destroy anything on the way out.

You guys can forget all my petty boost problems...it's destroyed. Three years of sweat, blood, toil, and over $12,000, and it's gone. I cried for the first time in over a decade. I didn't even cry at my Grandmother's funeral this past April, even though I was very close with her.

I was very close to buying forged Pauter or Crower connecting rods for the building of my engine this late spring, but on the advice of everyone on the forums, I kept the stock rods to keep costs down because I thought they were good for 400+ whp. At least now we know that couldn't be further from the truth. I HIGHLY doubt that I was making more than 300 whp when the rod self-destructed (the car was running pig-rich under JWT).

So for those of you who have NOT been paying attention to the "rod discussion," let me state this very clearly. STOCK KA RODS CAN NOT HANDLE BOOST. THEY CAN NOT HANDLE BOOST. THEY CAN NOT HANDLE BOOST. THEY CAN NOT HANDLE BOOST. THEY CAN NOT HANDLE POWER. THEY CAN NOT HANDLE BOOST.

Once more: STOCK KA RODS CAN NOT HANDLE BOOST.

These were stock KA rods, beefy units that were shotpeened from the factory like all KA rods. 97,000 miles on them. Never, EVER over-revved. 1000 miles on the freshly rebuilt engine.

I don't even know what to say. I'm still in shock. This summer has been the worst summer of my 19 year old life. Among a host of rather serious personal issues, I have spent weeks and weeks underneath the car trying to diagnose problems, taking the engine out, putting it back in, etc. I wish I'd just get hit by a car to make the summer even better, and in fact, I almost did, as I was collecting rod and block pieces off of the road!

I don't know what I'm going to do. I was just about to buy a new T3/T4 turbo. I'm leaving for North Carolina (to go to school at UNC-Chapel Hill) August 26th. I may just throw a stock KA in there and sell the thing. It's just not worth it to me anymore. I'm done with that damn car. Three years of dedication, and it was literally the ONLY thing that brought a smile to my face. It was my one and only unconditional friend. Nothing else makes me happy anymore. I've never been more depressed in my life.

I think it's time for a new project, a project that has good aftermarket support and cheap parts.

Another KA-T owner signing off, probably for good,

Marc"

As is patently manifest from the effusive language of my thread, I was simply beside myself, reeling. I was already in $2000 worth of debt from my parents anyway, and the failure seemed to all but extinguish the passion I had for the car.

But I received generous words of encouragement from Nico's KA-T forum, on which I had spent countless hours researching and offering up my own experiences. Here's what another KA-T owner,who recently blew up his built engine, had to say:

"My only advice for you is dont make any decisions on it just yet. I'm sure you're thinking about selling the car or parting it out... I know I thought (and do still think sometimes) about it. Still though, there are other ways to look at it it that might turn out to better for ya (and for me!). Rebuilding our engines this 2nd time around will create something SO much better than what we started with. Its not just a matter of getting back to what you've lost, but learning from the experience (and I KNOW you've learned so much already) and actually having the opportunity to apply that experience, now, into the very same project."

Along with magnanimous financial support from my parents, who saw how devastated I was and I guess felt pity for me (perhaps at how pathetically attached I was to a material thing?), I decided to rebuild it again, this time, of course, with forged connecting rods. Here's a pic of the stock rods versus the Crower's...

The Crower's are obviously far nicer and more robust rods--just look at how much higher of quality the fasteners are on the Crower's...

Anyway, with encouragement came optimism, and I poked fun at my situation with my "signature," which appears at the bottom of each post I make on the forums:

Back at the end of that summer, in the depths of my despondency, I wasn't even sure if I'd keep the car after it blew up after only 1000 miles on the freshly built, $3700 engine...

But I decided to keep it...she was (is) my first and only car and I've have had her for six years already. Six LONG years!

So over Christmas break ('05-'06), I dropped off a spare block (from Foster) at Precision Automotive in Simsbury...block got bored .020 over, surfaced, all that jazz, and rebuilt this time with CROWER forged connecting rods, not the crappy stock rods that apparently couldn't handle 16 psi from a small T3 @ 3500 rpm in 5th gear...In the meantime, I removed the rent engine (by myself).

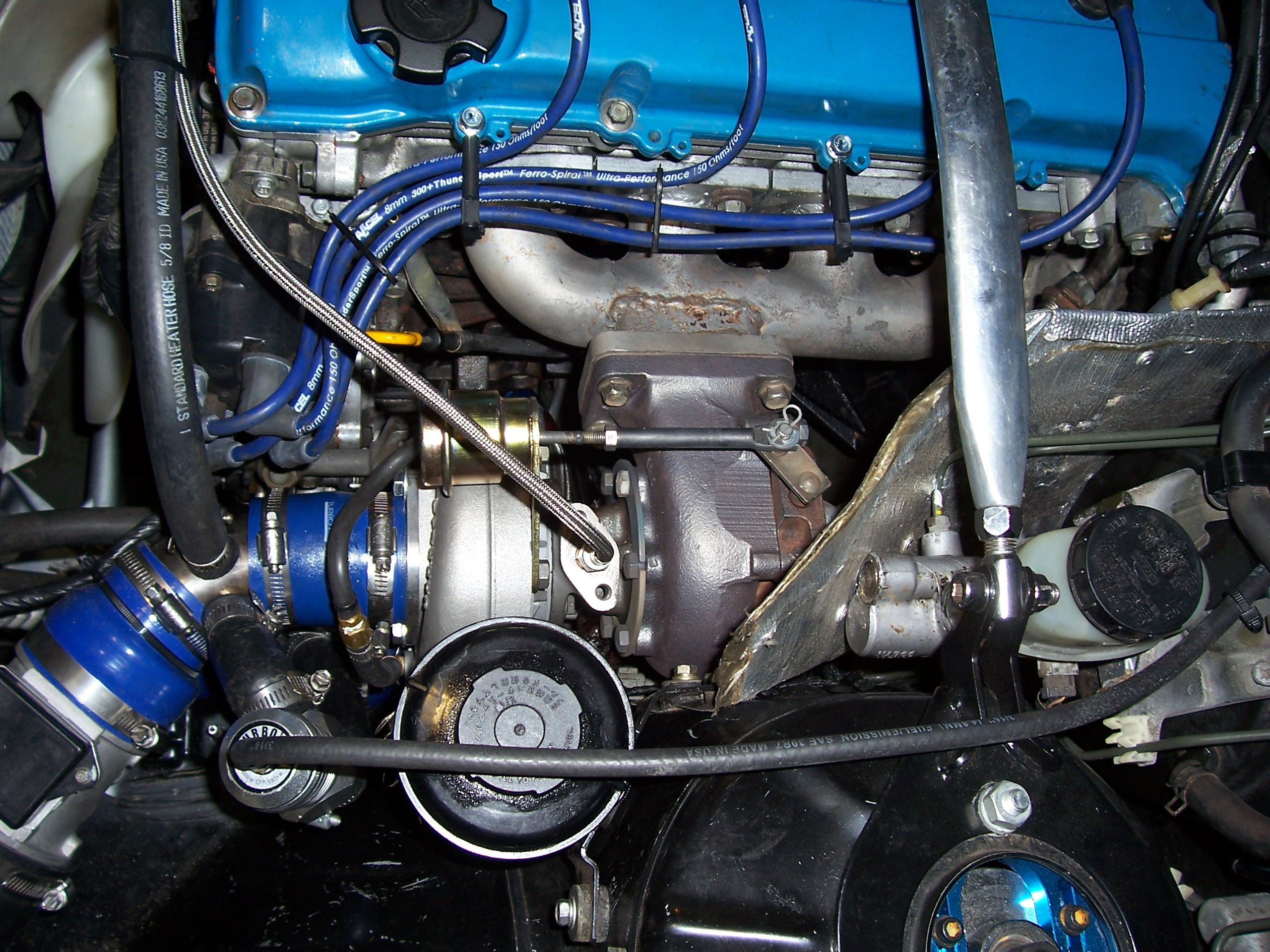

Anyway, the engine was ready by the time I got back for my spring break (March 10th)...so all that week, my dad and I were in the garage putting the engine back together/back in (I had the engine built only as a short-block). We had an uncharacteristically nice Saturday (temps were 62 degrees in CT!!) so we were able to do it outside and benefit from natural sunlight. We decided to undertake another project while we were at it. Check out the bling of anodized aeroquip fittings :-)

We moved the oil cooler (for some reason I'm one of the only KA-T owners I know who's actually running an oil cooler on a KA-T) from the front of the bumper, where it was wedged between the intercooler and AC condenser, to the passenger side of the bumper, where conveniently there was a huge air inlet. The oil cooler previously had been plumbed with just regular high-temperature, high-pressure rubber oil lines and nipple fittings, but my dad said it was a failure waiting to happen and absorbed the (rather expensive) cost of upgrading the oil cooler lines to Aeroquip, as well as the turbo drain line. We purchased a new Mocal sandwich adaptor plate (that fits in between the block and oil filter) that has an integrated thermostat, with -10 banjo fittings already installed; before I was running a remote thermostat, which worked fine, but which also added a lot of unnecessary lines. The oil cooler fit perfectly in the large air opening on the passenger side of the Nismo bumper.

In addition to the oil cooler, I also decided to FINALLY upgrade my T3 super 60, a turbo that wasn't exactly super (for my wants). If any of you remember, I praised this turbo for it's unbelievably quick throttle response and complete lack of lag, but lamented the boost drop-off and power waning past 5000 rpm. So I picked up another T3 super 60, brand new, internally wastegated still (yeah yeah, never got around to switching to external...too expensive, too complicated, yadda yadda yadda).

My old Super 60 had a .48 a/r stage 1 exhaust turbine and .60 a/r compressor, 60 trim. The NEW turbo is a .63 a/r, stage III turbine, 360 degree thrust bearing, 60 trim compressor, .60 a/r compressor. Got it brand new, including the external wastegate, from http://www.mjmturbo.com for $500. This was not an off the shelf unit either-the guy I got it from had it custom made with the *strange* internal wastegate discharge assembly so I wouldn't need to re-do the downpipe. MJM turbo happens to only be about 20 minutes from my house as well; the guy was very nice about it all (he just owns a warehouse, he doesn't actually have a sales shop) and very helpful...incidentally, he went to MIT and owns both a skyline GT-R and a twin-turbo Lotus Esprit v8 (he's pretty talkative!). This new turbo is quite a bit larger than the old one...here are some quick measurements of the outer diameter of the wheels:

Exh - Old=49.75mm, New=56.25mm

Comp - Old=52mm, New=60 mm

However, I would soon discover that the significantly larger, new turbo would literally stifle my dreams for over 300 rear-wheel horsepower. To see how I finally achieved this dream, go to the "final results" link in the top right!